The CMS Air Swept Classifier Mill System combines dynamic-impact grinding and particle size classification in a single continuous process. Independent drives for the Impact Rotor and Classifier Wheel allow the system operator to independently adjust their rotational speeds, thereby optimizing drag and tip speed control in producing the target particle size distribution. CMS Air Swept Classifier Mills are available from 5 HP (horsepower) to 600 HP.

Grinding & Classifying

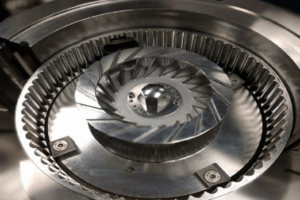

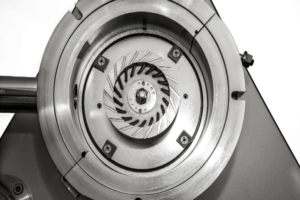

Grinding and Classifying are essential size reduction processes. The CMS Air Classifier Mill Grinding Zone configuration positions Impact Hammers mounted at the periphery of the Rotor Plate (below the Classifier Wheel), a reversible Multiple Deflector Liner enclosing the Rotor Plate, Hammers and a Deflector Assembly (shroud/baffle style) located above the Impact Rotor. The space between the Classifier Wheel and Deflector Assembly forms the Classification Zone.

How it Works

Air drawn into the mill via the Air Inlet entrains the feed material into an upward flow from below the Rotor Plate, dispersing the feed material to the Grinding Zone, where rotating Impact Hammers deliver high-speed impact, shattering and deflecting particles to the Liner and back to the Hammers. Size reduced particles flow to the Deflector Assembly, which then diverts material to the Classification Zone. Fine particles below the selected cut point will pass through the vanes of the Classifier Wheel to the product-and-air outlet, while coarse particles above the cut point will return to the Grinding Zone for further reduction.

Benefits of Air Swept Classifier Mills

First and foremost, reliability. Our air classifier mills are rugged, high-performance machines that will deliver superior final products at peak operational efficiency. Other benefits include:

- Durability. Long life.

- High-volume throughput on a single mill pass (lower unit cost of products)

- Consistent (repeatable) particle size fineness down to 5 µm

- Unrivaled energy efficiency

- Easy to maintain, cleanout, and operate

- Versatility over a wide range of materials <4 Mohs

- Embedded proprietary technologies | add unmatched performance |

With solid steel construction, the grinding/classification chambers are rugged and long-lasting. Internal components and wear parts are available in Stainless Steel, Abrasive-Resistant materials, Hardened Refractory metals, and Ceramic. For added safety, all mills above 5HP include a lid lift.

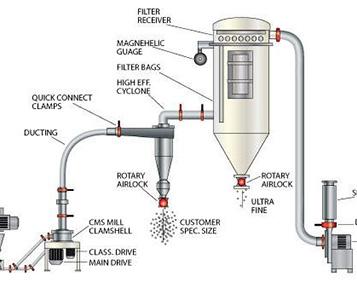

Air Swept Classifier Mill System Package:

- Air Swept Classifier Mill up to 600 horsepower

- High-Efficiency Cyclone

- Cyclone Classifier

- Dust Collector: 99.9% Dust-free

- Industrial Fan Set

- Control Panel

- Rotary Airlock Valves

- Embedded proprietary technologies

Air Classifier Mill Systems From CMS

At Classifier Milling Systems, our air swept classifier mill system facilitates streamlined processing applications. Systems are durable, reliable, and comparatively affordable, making it suitable for use in a diverse set of industrial applications. To learn more about our proprietary technology, contact us today. For assistance choosing and installing a milling system in your facility, request a quote.