For nearly three decades, Classifier Milling Systems (CMS) has been a premier design engineer and OEM manufacturer of market-leading particle size reduction equipment. We have designed materials grinding and classifying systems for Fortune 500s and numerous global leaders, and in many cases, CMS has raised the bar for standards of excellence. Among the most experienced size-reduction milling specialists in the world today, CMS has superior milling solutions for your business.

Our experienced engineers and specialists have the in-depth industry knowledge necessary to produce the perfect milling solution for a wide variety of materials used across industries, including:

- Basic Materials

- Industrial Chemicals

- Industrial Carbons

- Metallurgical

- Petrochemicals

- Minerals

- Refractories

- Abrasives

- Powder Coatings

- Pharmaceuticals, Nutraceutical

- Food & Agriculture

- Environmental Materials

- Waste Minerals Recoveries

- Air Quality Control (Emissions Mitigation) Systems

Particle Size Reduction

Particle size reduction is the process by which the physical particle size of inbound feed materials is reduced to granular or powder form, thereby increasing the surface area of the processed particles.

Choosing the appropriate milling system for your business begins with an understanding of the morphology (structure) of the raw materials you intend to process (hardness, bulk-density, aspect-ratio, flow properties, compression/tensile strength, melt point, thermal sensitivity, abrasiveness, stickiness, friability, moisture/absorption, toxicity, explosiveness), and, of course, the optimal particle size distribution curve for your product or application. Understanding the preceding will determine the mill type most likely best suited for your product. The vast majority of dry powders production by industry is accomplished by air classifying mills, jet mills, pin mills and hammer mills, which operate on the fundamentals of dynamic impact, attrition, and shearing, or by media mills which operate primarily on principles of compression.

At CMS, we pride ourselves on our in-depth understanding of the particle reduction process. With almost 30 years of experience, we can analyze the needs of any milling application, from raw material to final product, to ensure superior quality and optimum efficiency.

Air Swept Classifier Mill System

The Air Swept Classifier Mill System combines dynamic-impact grinding and particle size classification in a single continuous process. Independent drives for the impact rotor and classifier wheel allow the system operator to independently adjust their rotational speeds, thereby optimizing drag and tip speed control in producing the desired particle size distribution. CMS Air Swept Classifier Mills are available from 1 HP (horsepower) to 600 HP.

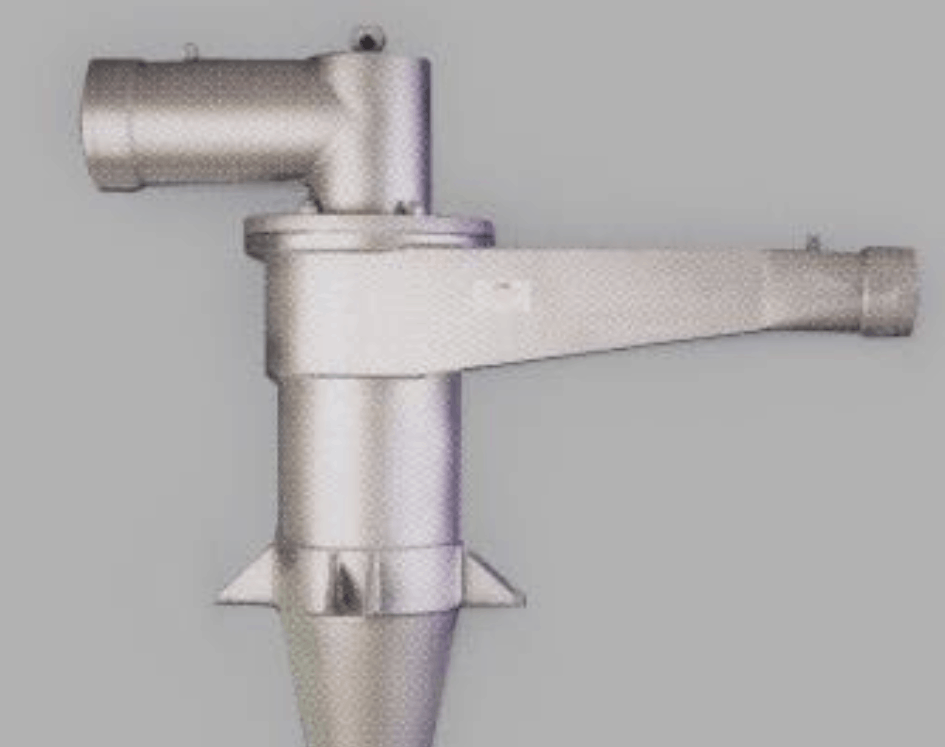

Cyclones & Cyclone Classifiers

CMS manufactures High-Efficiency Cyclones in a variety of constructions, including special alloys and refractory-lined and heavy-walled PSR resistant grinding mill construction, designed to meet extreme and challenging work conditions, such as work environments associated with high temperatures, materials abrasiveness or corrosive gases. CMS has installed Cyclone Classifiers for dry powder processing and separation of powder coatings, pigments, resins, bauxite, gypsum, limestone, cement, and numerous other basic and specialty feed materials.

Tabletop Lab System

The CMS Tabletop Lab System (notably ideal for batch testing and product development) has the particle size reduction and classifying functionality of CMS production level Air Swept Classifier Mills. Featuring easy portability for location changes, the 5 HP, Tabletop Lab System’s clamshell design and side-mounted control panel make the equipment particularly easy to use and clean. The system is dependable, energy-efficient, and ideal for continuous 50lb. batch testing | typically 150lb/hr. |

Pin Mill

The CMS Pin Mill is an excellent grinding mill option when your production targets call for particle sizes at medium fineness |> 35 µm D90|.

The Pin Mill incorporates a design configuration combining pins mounted to a stationary disc plate and a second rotational rotor plate. Material (via air) passes through the grinding zone, where centrifugal force accelerates the production materials through intermeshing shearing pins, then impacting the liner wall. Particle sizing generated by the pin mill is the product of rotor-disc tip speed, airflow rate, the feed rate of the material to be processed, and the morphology of the feed material. The Pin Mill series is available in models up to 150 HP. Additionally, CMS Pin Mills are available with a blow-thru air system | up to 1000 cfm |, which increases materials throughput and adds cooling of heat-sensitive materials.

Hammer Mill

Hammer Mills are rugged high-speed industrial impact mills (turbo mills) engineered to operate in high-volume production environments requiring continuous particle size reduction at > 45 µm D90, so commonly used in pharmaceutical, industrial chemical, food, mineral, and recycling industries.

Particle size reduction of feed materials by Hammer Mills occurs as a function of Rotor speed, feed rate, hit resistance, clearance between grinding plates and hammers, and screen size. Available in virtually indestructible fabricate or stainless steel, Classifier Milling System’s Hammer Mills are available in custom sizes up to 200HP. CMS warehousing maintains stocks of screens, liners, and hammers.

Particle Size Reduction Equipment from Classifier Milling Systems

At Classifier Milling Systems, we offer the highest quality milling equipment in the industry. Our competent and dedicated engineering and operational experts are seasoned designers of milling solutions for even the most complex and challenging applications.

For more information on our particle size reduction equipment, please contact us or request a quote.