Air Pollution in Industrial Environments

Maintaining optimal air quality in industrial settings is important to protect workers’ health and the longevity of the equipment they use. The Air Quality Index (AQI), which translates data collected from air pollutant monitoring stations into a scale, ranges from 0 to 500 and is divided into six categories to indicate the level of air pollution, with higher levels indicating greater health risks. High levels of air pollution can also create challenges for meeting increasingly stringent industry standards.

Classifier Milling Systems (CMS) manufactures robust dust collector systems with up to 99.99% efficiency. We use our proprietary filtering capabilities and vast experience working with industrial customers in various sectors to provide innovative and commercially viable solutions for even the most robust processing operations.

Understanding Dust Collectors/Filter Receivers

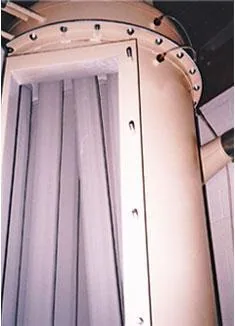

Industrial dust collectors from Classifier Milling Systems are specialized air filtration systems that capture and remove dust and other particulate matter from the air, preventing it from settling on surfaces or being released into the atmosphere. These dust collectors meet the strictest industrial and environmental air quality requirements with customized features and efficient design.

CMS dust collectors are designed for recyclable fines capture in dust-generating environments. These dust collectors meet the strictest industrial and environmental regulations, removing superfine dust for superior air quality control. These systems can use a standard radial inlet for most applications. In certain cases, tangential inlets may be used to produce a cyclonic effect for dense load separation.

Key Features of Dust Collectors/Filter Receivers

Our team engineers dust collector systems for custom configurations and tailors them to integrate with existing process systems. The following key features enable you to improve safety and efficiency.

- Precise engineering. Our systems are designed to protect workers from exposure to dust and other pollutants while delivering the maximum CFM of clean factory air.

- Improved performance. Our dust collectors can also help improve efficiency with reduced power consumption compared to most systems and a longer bag life.

- Advanced protection systems. Explosion protection systems exceed NFPA and ATEX standards to safely contain combustible dust.

- Dependable airflow technology. CMS dust collectors are equipped with a Venturi, which induces secondary air to the cleaning system to amplify the pulse cleaning of the filter bags.

The addition of our proprietary filtering capabilities and storage capacity provides our clients with an industry-leading solution for reducing air pollution.

Dust Collector Systems: Keeping Your Air Clean & Safe

Classifier Milling Systems (CMS) is a leading provider of high-performance dust collector systems, prepared to meet your most stringent air quality control requirements. We carry parts for most collection unit types, filter cages, and Venturis. We also provide solutions for the following:

- Gravity Separators (Drop-out boxes)

- Air Bin Vents

- Centrifugal Collectors

- Cyclones

- Hoods

- Baghouse Collectors

- Filter Bags, Cages, and Cartridge Bags

- Venturi Systems

- Pulse Jet Collectors

Our products are backed by a range of services, including repairs and servicing existing dust collection systems.

Air quality control is an essential part of your operation, and is easier with support from CMS. We customize dust collector systems to align with regulations and workflows, so you know you’ll have exactly the right system for the job. Contact us today to learn more about our dust collectors or get your order started.