Classifier Milling Systems manufactures high-efficiency cyclones in various constructions, including special alloys and refractory-lined cyclones, which are designed to meet extreme and challenging work conditions, such as work environments associated with high temperature or corrosive gases. CMS has installed cyclone classifiers for processing powder coatings, pigments, resins, bauxite, gypsum, limestone, cement, and numerous other feedstock materials.

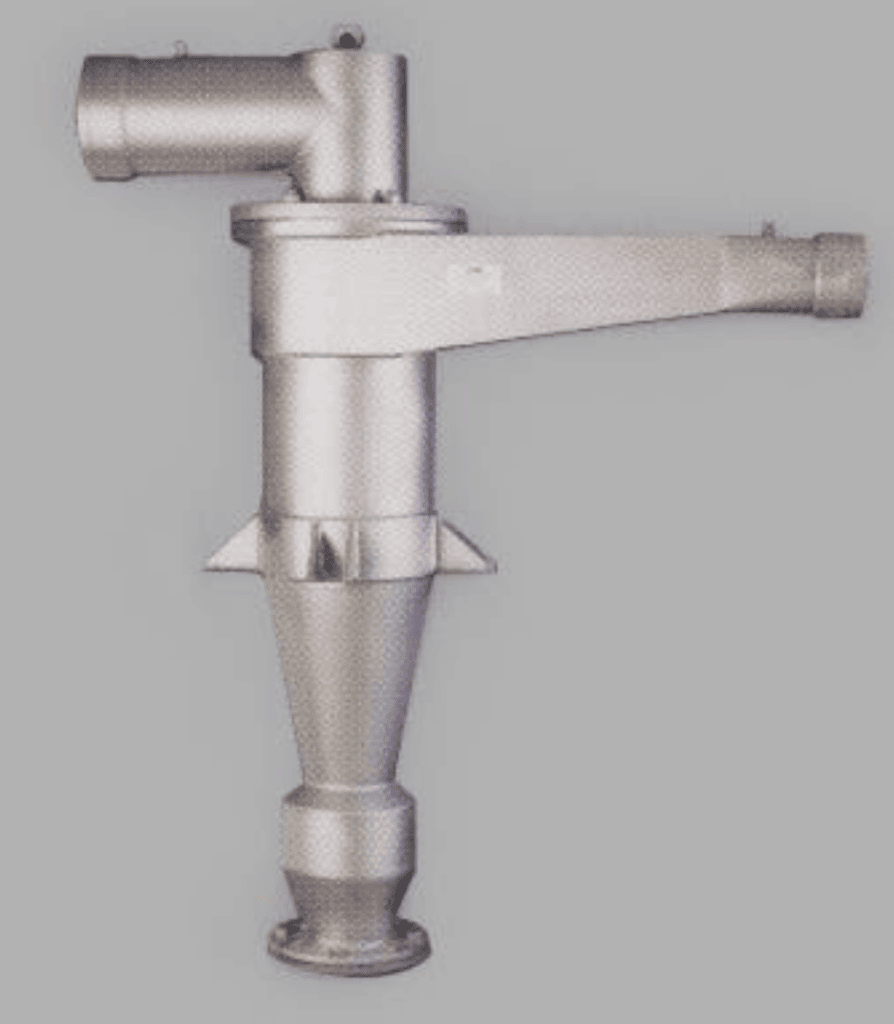

Cyclone & Cyclone Classifiers from Classifier Milling Systems

- Available in stainless steel and carbon steel construction

- CMS offers a specialized heavy-walled grinding mill for high-pressure production, combinations of pressure and extreme temperature, or abrasiveness. Also available with PSR 11

- The cyclone body is one-piece welded construction |internal welds ground smooth |

- Easy cleaning extended acceleration inlet tube

- Access through the top when the outlet tubing and exhaust are removed

How it works:

Airflow enters the cyclone’s inlet spiral, then directs fine material through the vanes of the rotating classifier wheel while recirculating the coarse material for further grinding and separation. The cut point setting of the classifier wheel regulates the separation between fine and coarse material, while dust materials will discharge through an upper outlet duct to a dust collector. CMS Cyclones enable the operator to dial in cut points as low as 10 µm d50.

CMS Cyclone

CMS Cyclone Classifier

CL Cyclone Classifier