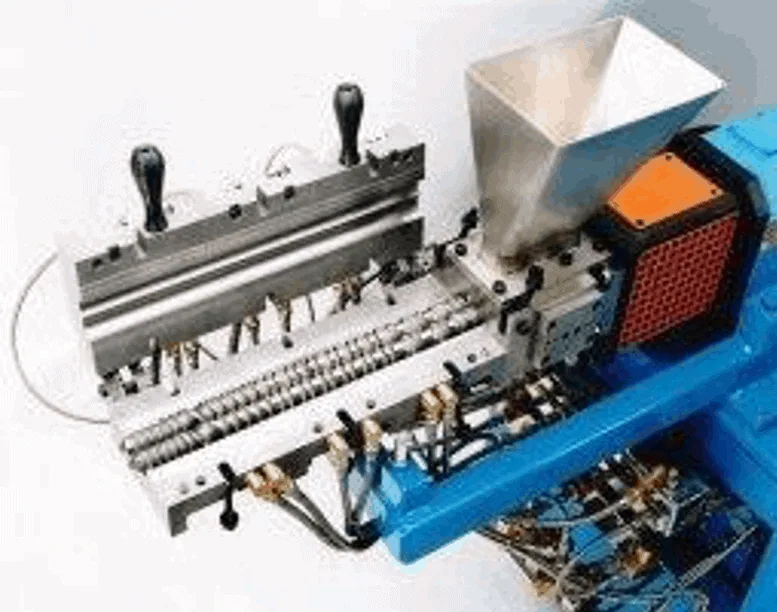

The pin mill consists of two counter-facing discs with pins mounted to a stationary or counter-rotating disc plate and a second rotational rotor plate. Material fed to the grinding chamber is pulled by the centrifugal force exerted by the spinning disc(s), flowing the production materials through the pins to collide with the liner wall. The material at particle sizes below the cut point will exit the mill to a cone hopper, while material above the cut point recirculates for continued grinding. Also called a Centrifugal Impact Mill, the pin mill offers several benefits over other grinding mill types:

- Micronized particle sizing – Pin mills can meet size reduction targets as low as 2 µm.

- Uniform product – Pin mills, more than most other mill types, are known for producing a highly homogenous product.

- Dust-free – Pin mills do not expel dust during operation, therefore eliminating nuisance-dust from grinding, and nearly eliminating product waste.

- Energy consumption – Pin mills are energy-efficient.

- Small footprint – Pin mills are relatively small grinding mills easily integrated into milling systems flows.

- Flexible use – Pin mills can be used to mill dry or moist material. Moreover, the particle size can be altered ‘on the fly’; without having to shut the mill down.

When looking for grinding mills, the pin mill is one to keep in mind. Want to learn more? Give us a call or contact us!