About Mill Components & Parts

Classifier Milling Systems (CMS) supplies precision-built mill components and replacement parts that keep air classifier mills operating at target cut points, throughput, and uptime. We provide classifier wheels, liners, rotors, hammers, seals, and bearings for systems ranging from pilot scale to 400 HP, with expedited fulfillment to minimize downtime and restore productivity quickly.

Our engineering team aligns parts with the process variables that most strongly influence classification: airflow, rotor speed, and feed-to-air ratios. This ensures stable D50/D97 results, limits over-grinding, and reduces heat buildup in temperature-sensitive products. By designing mill components around these critical parameters, CMS helps operations maintain consistent quality and reliable output.

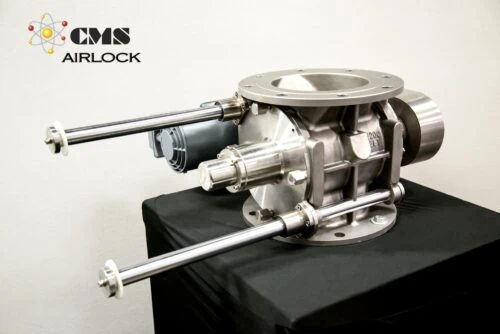

Classifier Milling Systems’ state‑of‑the‑art Quick Clean Rotary Airlock Valve is engineered for processors who refuse to compromise on efficiency, hygiene, or durability. Available in both stainless steel and carbon steel, this valve is built to withstand demanding industrial environments while maintaining exceptional precision in material handling. Its robust construction ensures long service life, consistent performance, and compatibility with a wide range of products—from fine powders to abrasive materials—making it an ideal choice for industries where reliability is non‑negotiable.

What truly sets the Quick Clean design apart is its ingenious rail‑mounted opening system, allowing operators to slide the housing open effortlessly for rapid, unobstructed access. This eliminates the time‑consuming disassembly required by traditional airlocks, dramatically reducing downtime and simplifying sanitation procedures. Whether your priority is faster changeovers, improved product purity, or enhanced operational safety, the Quick Clean Rotary Airlock Valve delivers a smart, streamlined solution that keeps your production moving with confidence.

Materials of Construction

Mill component construction materials directly influence milling efficiency and product quality. In an air classifier mill, classifier wheels and guide vanes control the cut point, while tip speed and liner geometry dictate impact intensity. To resist abrasion and contamination, CMS constructs mill components from stainless steel, ceramics, tungsten carbide, and other materials known for their durability in demanding environments.

Precision fits on rotors, seals, and bearings help prevent bypass and leakage that widens distributions. When leakage occurs, product uniformity and energy efficiency decline. For this reason, CMS emphasizes ongoing upkeep and timely replacement of damaged or worn parts to avoid overload, heat accumulation, and off-spec fines. With a maintained inventory and installation support, CMS ensures reliable replacements are always available.

| Product Name | Stellite | Tungsten | Carbide | Mild Steel | Stainless Steel | Ceramic |

|---|---|---|---|---|---|---|

| Set of Block Hammers | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Hammer Rotor Disc | ✔ | ✔ | ||||

| Wear Plate | ✔ | ✔ | ||||

| Pin Rotor Plate | ✔ | ✔ | ||||

| MD Liner Set (5 pieces) | ✔ | ✔ | ✔ | |||

| Smooth Liner Set | ✔ | ✔ | ||||

| One Piece Reversible Liner | ✔ | ✔ | ||||

| Classifier Wheel (24, 36, 48 Vane) | ✔ | ✔ | ||||

| Top Ring Design | ✔ | ✔ | ||||

| Straight Vane Design | ✔ | ✔ | ||||

| Spindle Assembly (Coaxial) | ✔ | ✔ | ||||

| Diverter Assembly (baffle/shroud) | ✔ | ✔ | ||||

| Air Dispersion Ring | ✔ | ✔ | ||||

| Rotor Assembly (IND) | ✔ | ✔ | ||||

| Classifier Assembly (IND) | ✔ | ✔ |

Outdated Equipment Refurbishment Solutions

CMS provides equipment refurbishment to extend the life of outdated air classifier mills and restore performance without the full cost of replacement. Our team evaluates wear on classifier wheels, liners, rotors, and seals, where erosion, pitting, and fatigue often reduce efficiency. Components can be re-machined to OEM tolerances or replaced with upgraded materials for higher abrasion or heat resistance.

Refurbishment can also include the modernization of obsolete controls and drives. These components can be swapped for new variable frequency drives (VFDs) and PLC-based automation for improved cut point stability. By providing equipment refurbishment capabilities, CMS helps businesses reduce unplanned downtime and improve efficiency.

Benefits Of Upgrading Your Existing Machines

Modernizing existing mills provides tangible production and cost benefits:

Higher Capacities

When classifier wheels, rotors, or liners show signs of wear, mills lose efficiency and output begins to lag. Replacing these parts with CMS-engineered components restores original throughput and helps plants keep pace with production targets. This gives facilities the confidence to meet higher demand while continuing to operate on existing equipment.

Tighter Distributions

Worn surfaces and misaligned parts can widen particle size distributions, leading to oversize material and wasted fines. By supplying new classifier wheels, guide vanes, and other precision components, CMS enables mills to regain sharp cut point control. Restored accuracy improves consistency in industries where even small deviations can impact quality.

Lower Temperatures (And Higher Throughput)

As components degrade, friction and heat buildup become more pronounced, limiting how fast a mill can safely run. Replacement parts from CMS improve airflow and reduce grinding friction, allowing mills to maintain cooler operating temperatures. This supports higher throughput for heat-sensitive materials without risking product damage.

Energy Savings

Aging drives, liners, and rotors often force mills to draw more power than necessary. By refurbishing or replacing these components, CMS helps plants return to energy-efficient operation. Lower energy consumption reduces operating costs and contributes to a more sustainable production process while preserving milling performance.

Why Choose CMS?

Classifier Milling Systems delivers high-quality mill components and replacement parts designed to match the requirements of existing classifier mills. Our parts are manufactured to OEM or enhanced specifications, ensuring compatibility and reliable performance across a wide range of industrial applications. With an extensive inventory and expedited fulfillment, we help minimize downtime and restore equipment efficiency quickly.

Beyond supplying parts, CMS provides on-site installation, alignment, and commissioning services to validate performance improvements. Our engineering and field service teams also consult on system upgrades, helping customers align component choices with process goals, product needs, and compliance requirements.

Request a quote today to learn more about our mill components and replacement parts.