Try our Portable Tabletop Lab System!

Leave a Comment

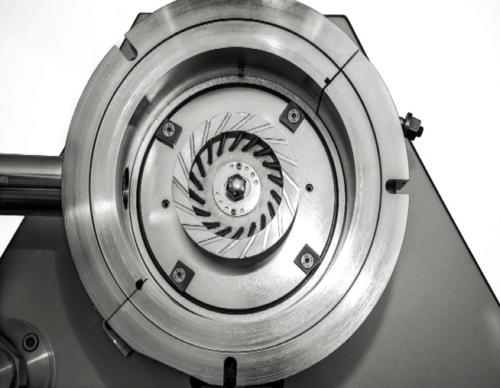

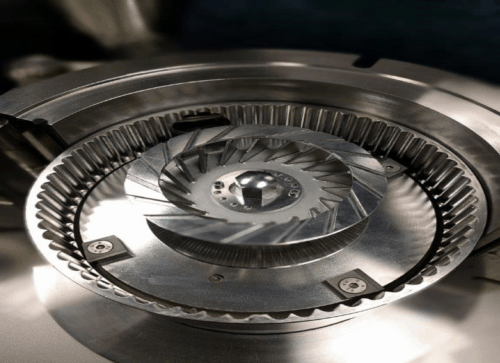

If you’re looking for the functionality of our Air Swept Classifier Mill System, but need a smaller machine, the Tabletop Lab System is the perfect choice for you! It is the most convenient grinding system we offer and has just as many capabilities and impressive features as our larger machines.

The Tabletop Lab System is a portable unit initially designed for batch testing and product development. It is the moveable, tabletop version of the commercial scale Air Swept Classifier System. The Tabletop unit is rated to grind feed materials at a rate of +/-150 pounds/hour continuously (depending upon particle size distribution targets and feedstock Mohs hardness), and is ideal for temperature-sensitive source materials. The Tabletop Lab System incorporates a stainless steel rotary valve, screw feeder with a built-in cartridge filter, stainless steel cyclone, blower set with an inlet and outlet silencer, side-mounted control panel. The Tabletop Mill also features a clamshell design for quick and easy cleaning.

Want to learn more? Give us a call or contact us!

In the processing industries, fierce competition and keeping up with ever-changing regulatory requirements are some of the challenges one faces when bringing new products to the market. Which leaves no room for error on the processing line — so get it right in the laboratory before going to commercial scale. The CMS ultra-modern laboratory test facility can play an essential role in defining and helping you to meet commercial-scale challenges.

In the processing industries, fierce competition and keeping up with ever-changing regulatory requirements are some of the challenges one faces when bringing new products to the market. Which leaves no room for error on the processing line — so get it right in the laboratory before going to commercial scale. The CMS ultra-modern laboratory test facility can play an essential role in defining and helping you to meet commercial-scale challenges.