Graphite on Center Stage in Lithium-Ion Battery Manufacturing

4 Comments

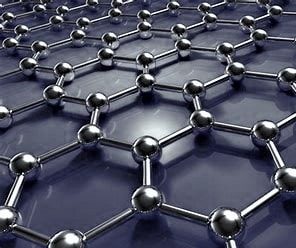

Spherical Graphite (SG), natural graphite flake micronized and shaped to spheroidal form, has moved to center stage in the battery industry where SG is increasingly the preferred anode material of Li-ion batteries, deployed in residential and industrial energy-grid storage, electric vehicles, and consumer devices.

SG packed anodes are proving to outclass the results of anode materials alternatives, a function of the inherent properties of natural graphite flake (conductivity, heat-resistance, intercalated (layered) morphology, and the milled spheroidal shape. When compared to alternatives (including synthetic graphite), SG packed anodes will have superior (high) tap density, charging rates, and volumetric energy capacity.

CMS designs and manufactures the leading graphite micronizing milling systems (typically 150 – 400 HP), which are capable of achieving product grinds of all standard graphite powder products down to +/-5 µm. CMS also offers mill systems for the production of battery-grade Spherical Graphite.

Want to learn more? Give us a call or contact us!