Classifier Milling Systems Corp. (CMS) offers air classifier mill systems that combine internal air classification with dynamic impact grinding to achieve precise, energy-efficient particle size reduction.

The separate drives for the classifier wheel and impact rotor in our air swept milling equipment let operators independently adjust and control their rotational speeds, optimizing the tip speed and drag for controlled target particle size distribution. CMS air swept classifier mill systems range from 5 HP to 600 HP and can accommodate full-scale and pilot-scale production projects.

Learn more about our classifier mills, including their specifications and benefits for certain applications.

Grinding and Classifying

In the CMS Air Swept Classifier Mill System, grinding and classifying are vital to the size reduction process and occur simultaneously within the same chamber.

The grinding zone consists of:

- Impact hammers. Securely mounted at the edge of the rotor plate, the impact hammers create high-speed collisions to reduce feed material.

- Deflector assembly. Located above the impact rotor, this shroud/baffle style assembly is designed to redirect partially ground materials toward the classifier.

- Multiple deflector liner. This reversible liner encloses the grinding zone components.

- Classifier wheel. To ensure the final output adheres to precise size specifications, the vanes on the classifier wheel only allow particles below a set size cut point to pass through.

The classification zone is the space located between the deflector assembly and the classifier wheel that effectively separates both coarse and fine particles.

How It Works

- An air inlet at the bottom of the milling system draws air into the equipment.

- The air stream catches the feed material, carrying it upward into the grinding zone.

- High-speed rotating impact hammers create deflections off the liner and mechanical collisions to reduce the feed material into smaller particles.

- Once grinding is complete, the air and particle mixture continues traveling upwards to the deflector assembly, which directs the air stream toward the classification zone.

- The classifier wheel separates the particles below the cut point, allowing them to exit via the air stream as the final product.

- Oversized particles return to the grinding zone for further processing.

- The closed-loop cycle continues until all material matches the required specifications.

Benefits of Air Swept Classifier Mills

The CMS Air Swept Classifier Mill combines efficiency, robust performance, and long-term value to deliver exceptional final products. Key benefits include:

- Custom engineering. Mill components are constructed from refractory metals, ceramics, or stainless steel to meet the needs of a specific application.

- Durability. Rugged internal chambers and solid steel construction provide long-lasting service life.

- Ease of use. Our equipment is designed for user-friendly operation with fast cleanouts and simple maintenance.

- Energy efficiency. The design optimizes rotor dynamics and airflow, significantly reducing energy consumption.

- High throughput. Our mills reduce operating costs by processing large volumes of feed material in one pass.

- Material versatility. They can process materials with a <4 hardness on the Mohs scale.

- Precision. Users have consistent particle size control (as low as 5 µm).

- Safety features. All units with power >5 HP include a lid lift to ensure safe, easy access for maintenance.

These combined advantages make CMS milling systems a reliable option for industries requiring maximum operational uptime and precise quality control.

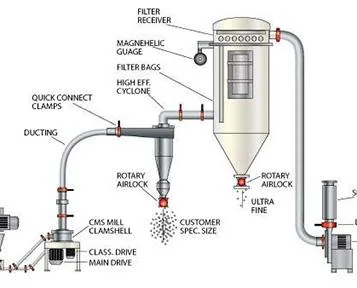

Air Swept Classifier Mill System Package

CMS delivers standard Air Swept Classifier Mill Systems as a fully integrated package that includes the following components, tailored for simple installation and optimal performance:

- Air swept classifier mill (up to 600 HP)

- Cyclone classifier

- Dust collector (99.9% dust-free)

- High-efficiency cyclone

- Industrial fan set

- Integrated control panel

- Rotary airlock valves

In addition to our embedded proprietary performance technologies, CMS milling systems support scalable deployment and dependable operation across various production needs.

Air Classifier Mill Systems From CMS

CMS Air Swept Classifier Mill Systems are reliable, durable, and affordable, making them ideal solutions for many challenging industrial applications. Request a quote to learn more about our air swept classifier milling systems and how they can meet the demands of your next project.