The two most common grinding machines used by industry are the pin mill and hammer mill. Both mills have fundamentally unique features that make them suited for a wide range of materials production.

Pin Mill

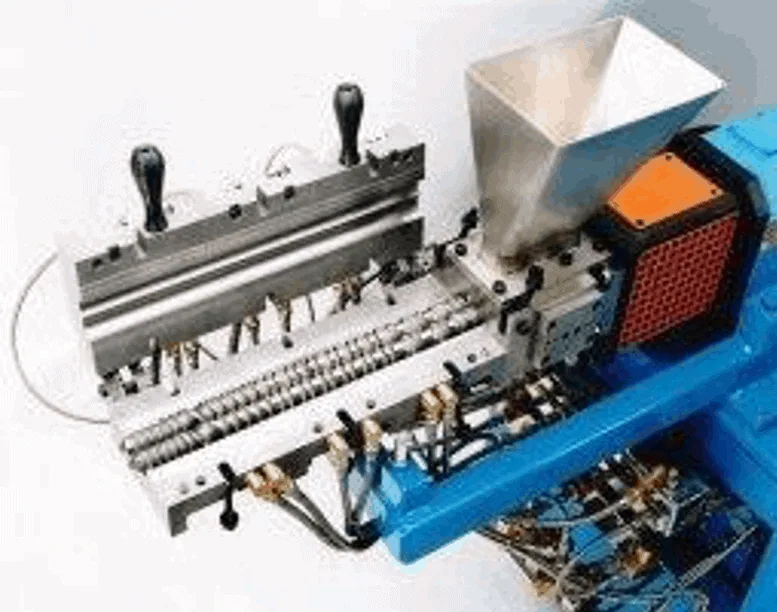

The Pin Mill, unlike the Hammer Mill, consists of a series of pin breakers hinged to discs in the grinding head where it delivers high-energy impact. Pin Mills use shearing and impact methods; however, with a faster tip speed of intermeshing pins when compared to a Hammer Mill. Centrifugal force brings the particle sizes to the grinding chamber’s periphery for collection or further processing. The milling process will produce particle sizes down to ultra-fine micronized sizes +/- 10 µm. Particle sizing generated by the pin mill is the product of rotor tip speed, airflow rate, the feed rate of the material, as well as the morphology of the feed material. The milling process balances additions and reductions of airflow, feed rate, and rotor speed.

Hammer Mill

The Hammer Mill, one of the oldest and widely used grinding mills, typically consists of four or more hammers attached on a central shaft enclosed by a metal casing. The mill performs particle size reduction via high-speed impact of hardened steel rotating hammers. Particle size reduction occurs in three actions: repeated hammer impact, particle collisions with the chamber wall, and particle-to-particle impact. Screens (set at a specified cut point) retain coarse particles for further grinding while allowing product sizes below the cut point to pass. Achieving the target particle sizing is a function of rotor speed, feed rate, hit resistance, clearance between grinding plates and hammers, and screen size.

At Classifier Milling Systems, we manufacture both pin mills and hammer mills as well as the leading air classifier mills and a broad range of milling technologies and products designed to give you the fine grind that suits your unique needs. We are a dedicated team with expert knowledge of particle size reduction. We guarantee exceptional service every time. We also guarantee performance!

5 Comments

Fahim Fazly

Dear Sir/Maam

we are using hammer mill and pin mill in our salt refinery factory in Afghanistan and we use sea salt, in recent years we are not able to get crystal salt (like sugar) the particles are very fine after passing of hammer mill. The salt particles are very tiny in our production we only get 30% crystal salt the rest is to fine which not needed for us.

Please guide us with a solution.

Shaylee Packer

As you mentioned, a hammer consists of four or more hammers, they shape the object by repeating actions. This would be an interesting thing to see in slow motion and see exactly how it works. There are many things that can come into factor when choosing the size and shape of the item. https://www.pharmasurplusequipment.com/index.php/product/description/FITZPATRICK-DAS06-Fitzmill-Commutator-Stainless-steel-

Nasr Hussein Nasr

which mill gives more fine particles hammer or pin mill , which suitable for grinding wet powder

Jeffrey Senodivila

If materials to be grind is leaves for example a plant leaves, which is better the pin mill or the hammer mill?

Small And Medium-sized Extraction And Concentration Units

Hey There. I found your blog using msn. This is a really well written article.

I will be sure to bookmark it and come back to read more of your useful information. Thanks

for the post. I’ll definitely comeback.