In the processing industries, fierce competition and keeping up with ever-changing regulatory requirements are some of the challenges one faces when bringing new products to the market. Which leaves no room for error on the processing line — so get it right in the laboratory before going to commercial scale. The CMS ultra-modern laboratory test facility can play an essential role in defining and helping you to meet commercial-scale challenges.

In the processing industries, fierce competition and keeping up with ever-changing regulatory requirements are some of the challenges one faces when bringing new products to the market. Which leaves no room for error on the processing line — so get it right in the laboratory before going to commercial scale. The CMS ultra-modern laboratory test facility can play an essential role in defining and helping you to meet commercial-scale challenges.

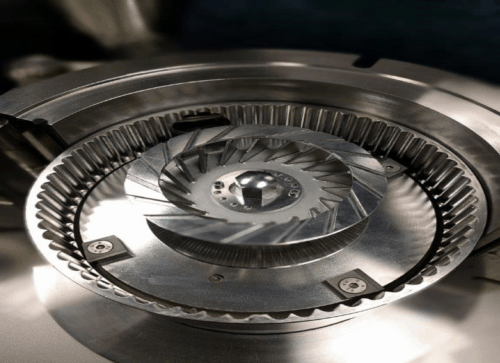

From grains and coffee to powder paints, pigments, and industrial minerals, the list of materials that CMS has evaluated, or formulated and engineered custom milling systems, is very long. What we’ve learned from thousands of materials trials will save you time in arriving at the optimal milling techniques, methods, and systems.

We can help. We encourage you to send us a sample!

1 Comment

Juzer Jangbarwala

We produce synthetic graphite from catalytic cracking of methane. The composition is single crystal graphite, and the size if the fibers is between 1-3 microns. We would like to investigate processing this material to make the particles spherical in the size range that is required by the Li ion battery markets.

We would like to start by sending you a sample and get a lab assessment done for moving further with the project.